Categories:Uncategorized

Numbers:24082 customers have paid attention to it

Hotline:13888888888

BSCO Automated Production Management System (MES System)

BESCO Automated Production Management System (MES System) is a star product suitable for batch formulation manufacturers such as paints, coatings, fine chemicals, pharmaceuticals, and food. It can truly help the factory realize the transformation of the whole process of on-site operation mode from raw material storage, material measurement, batching to discharge. It uses computer network communication, material barcode and PLC control and other technologies to realize the accuracy of material weighing operations through centralized control of production formulas, and guide workers to configure production in strict accordance with the specifications of standard operating procedures (SOP), and finally complete the electronic batch operation record of the workshop and the transparency of the batch production implementation progress.

Functional features

1. Centralized control of recipe version

The factory can choose to import existing product recipes from RP, third-party independent recipe systems or EXCEL files, or create new recipes directly in the system and form different versions of recipes, and the recipe-related data will be stored in a database and can be directly used for production after review.

2. Transparency of real-time progress of batches

FACTORIES CAN CHOOSE TO IMPORT THE BATCH PRODUCTION PLAN FROM THE SHOP FLOOR BY IMPORTING FROM AN ERP OR EXCEL FILE, OR THEY CAN CREATE NEW PROCESSING BATCHES DIRECTLY IN THE SYSTEM. Through on-site progress feedback, managers can directly understand the production progress.

3. Precision of weighing operations

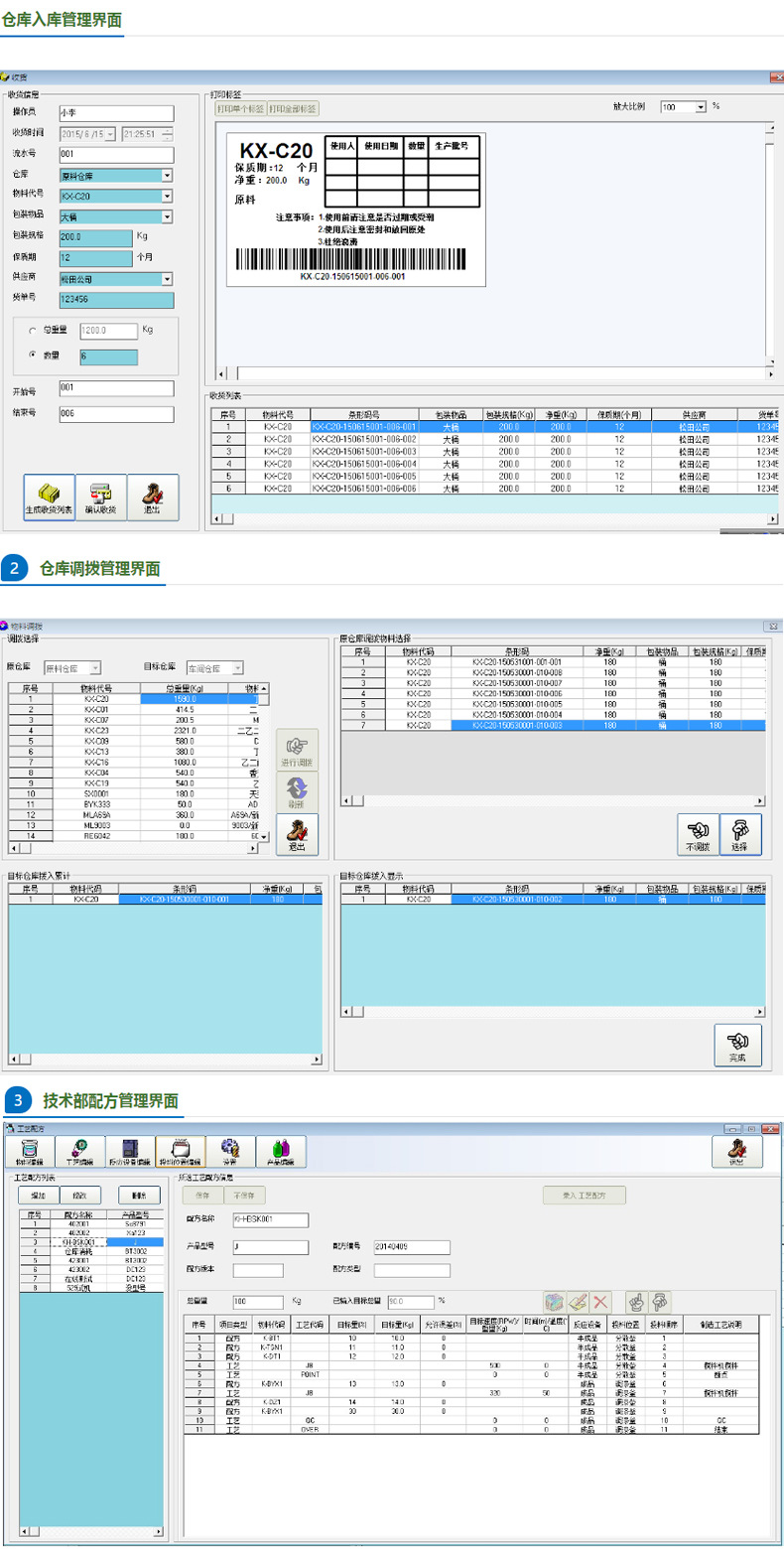

For raw materials received in the warehouse, barcode labels can be printed in the format for material identification. In the weighing area, according to the production plan and recipe, the system guides the workers to weigh the materials, and then prints out the barcode of the small packaging materials. The system can use barcode scanning to check and prevent errors in material types, and strictly control weighing deviations through the interface with the electronic scale. The system supports two different operating modes of mobile weighing and fixed weighing, and can be integrated with mobile weighing trolleys (or AGV trolleys).

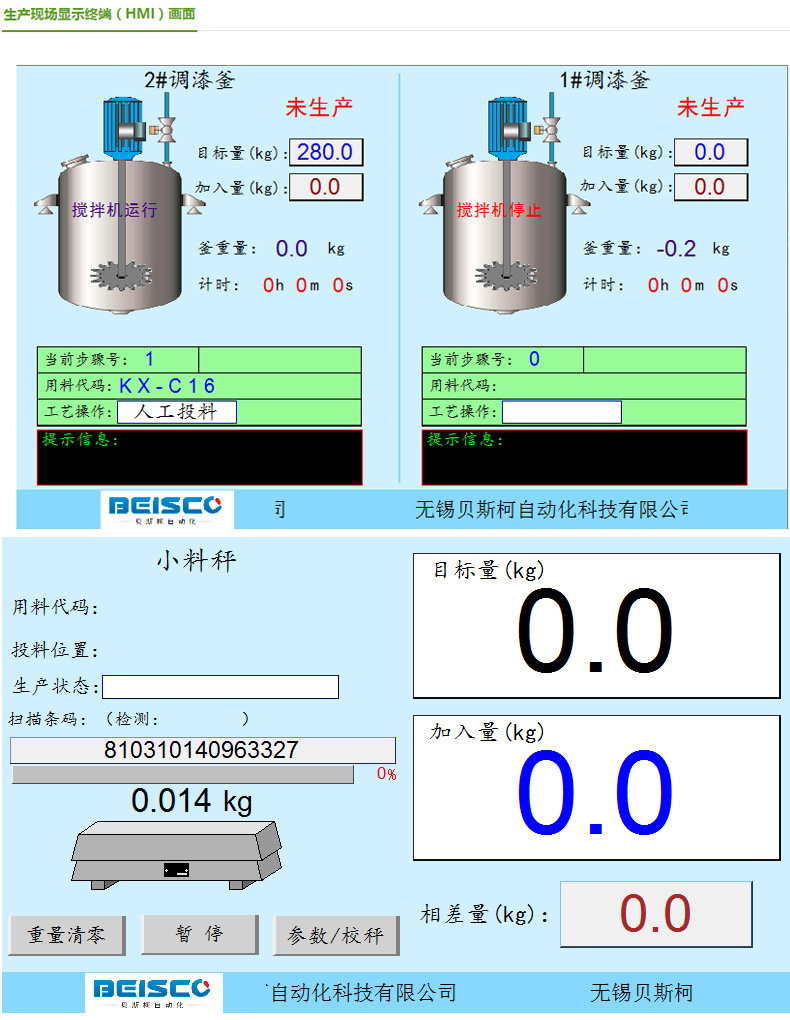

4. Standardization of the production industry

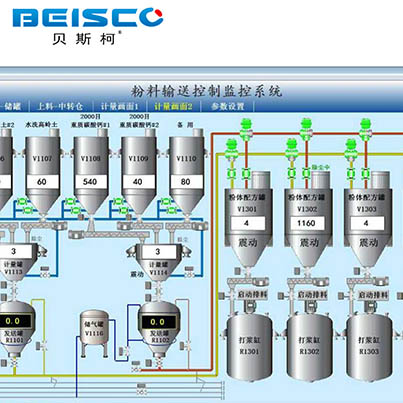

Workers in the production site of the configuration monitoring workstation, according to the system prompt of the production plan to carry out processing production. The system guides workers to feed according to recipe and standard operating procedures (SOPs). For the manually added materials, workers use barcode scanning to check; For automatically added materials, the system can be linked with the control system. Some important process parameters such as temperature, pressure, stirring speed, etc. are monitored, and the overrun warning function is provided.

5. Strict permission control

All operations of the system need to be authorized and recorded in detail, and permissions can be divided into multiple levels as needed.

6. Electronic batch production records.

The system provides a variety of production reports, including weighing reports, batch production records, daily production records, monthly statistical records, team production records, alarm records, etc., and provides report customization services.